producing demands are evolving fast, requiring precision and efficiency to remain competitive. a person key location driving modernization is the use of personalized fixtures and jigs in production procedures. These vital equipment ensure the precision and effectiveness of producing traces, especially when personalized to unique marketplace needs. By integrating custom solutions, organizations can meet up with exclusive production problems although reaching bigger quality and maximizing output. This website explores how customization in fixtures and jigs is reshaping manufacturing and highlights its Positive aspects for precision industries.

Table of contents:

Tailoring Fixtures to unique manufacturing demands

the entire process of planning Custom Jigs for Specialized jobs

great things about Collaborating with Manufacturers for Customized options

serious-World Examples of Custom Fixtures maximizing productiveness

Tailoring Fixtures to certain manufacturing Requirements

Fixtures are integral to making sure that parts continue being fixed and adequately aligned in the production approach. personalized fixtures are created with certain generation prerequisites in your mind, adapting to unique solution dimensions, workpiece stability demands, and operational needs. For example, manufacturers during the automotive or aerospace sectors depend on really specialised fixtures to handle advanced assembly procedures though protecting tolerances inside microns. These customizations ensure that Just about every output phase is repeatable and correct, doing away with errors that could compromise excellent or protection. With precision mechanical areas getting the benchmark for prime-executing industries, tailored fixtures serve as the spine in their functions.

the whole process of building Custom Jigs for specialised jobs

personalized jigs are priceless when manufacturing strains need regular precision and effectiveness. the method commences with comprehension the producing necessities and operational issues faced by a company. By conducting a detailed design consultation, brands can make jigs that simplify complex manufacturing techniques even though cutting down cycle periods. no matter if for drilling, reducing, or assembly, tailored jigs convey regularity to large-volume creation environments. They can be normally fabricated employing resilient products like steel or aluminum, effective at withstanding extended creation runs with no compromising overall performance. Advanced manufacturing technologies including CAD software package or 3D modeling further streamline the look course of action, ensuring the jig integrates seamlessly into present workflows. The end result? hugely efficient creation strains that execute jobs with unparalleled precision.

advantages of Collaborating with companies for custom-made answers

picking out to personalize fixtures and jigs unlocks a spread of advantages for suppliers looking to continue to be aggressive. First of all, customization maximizes operational effectiveness, as tailor-made answers align beautifully with the requirements from the production line. Next, collaboration with knowledgeable suppliers ensures specific product assortment and style and design, translating to tough components which can be created to very last. And finally, tailor made answers enable for more rapidly manufacturing cycles and lowered downtime, as devices and tooling are optimized for smooth functions. participating responsible partners like Shenzhen Yongxinglong Industrial growth Co. for customized jigs and fixtures ensures high merchandise top quality by means of qualified craftsmanship and Superior production procedures. By Doing the job intently Using these specialists, organizations also acquire use of chopping-edge innovations that strengthen prolonged-expression effectiveness.

genuine-earth Examples of tailor made Fixtures Enhancing productiveness

functional apps of customized fixtures and jigs demonstrate their important part in modern production units. For illustration, Shenzhen Yongxinglong collaborates intently with automotive and electronics producers to generate specialised welding fixtures. These fixtures make certain seamless alignment of vehicle components for the duration of automated welding operations, causing more powerful bonds and minimized assembly problems. in the same read more way, customized jigs for electronics production revolutionize precision assembly, enabling flawless placement of micro-factors. These advancements aid enterprises satisfy stringent market standards by acquiring steady precision. By incorporating custom made patterns, industries for example aeronautics and heavy equipment are able to cut down cycle situations significantly, maximizing both equally productiveness and profitability.

Customization in fixtures and jigs producing is A necessary financial investment for industries in search of excellence. personalized answers from knowledgeable companies like Shenzhen Yongxinglong Industrial Development Co. unlock unparalleled precision and performance, guaranteeing businesses can fulfill their output targets though protecting a competitive edge. From lowering cycle occasions to boosting product good quality, the many benefits of custom-made fixtures and jigs are simple. do you think you're all set to elevate the effectiveness within your production line? Call Shenzhen Yongxinglong to learn more regarding how their high-quality jigs and fixtures can satisfy your exact needs.

Alana "Honey Boo Boo" Thompson Then & Now!

Alana "Honey Boo Boo" Thompson Then & Now! Amanda Bynes Then & Now!

Amanda Bynes Then & Now! Richard "Little Hercules" Sandrak Then & Now!

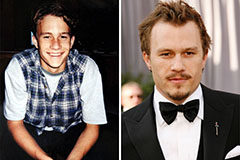

Richard "Little Hercules" Sandrak Then & Now! Heath Ledger Then & Now!

Heath Ledger Then & Now! Dawn Wells Then & Now!

Dawn Wells Then & Now!